Why Call GPRS Prior to Concrete Core Drilling?

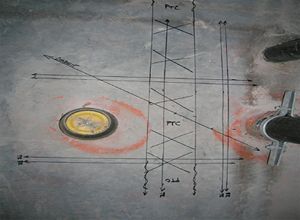

Example #1: This is a picture of an area that was core drilled prior to checking the slab with ground penetrating radar. You can see that there are two conduits in the floor and you can also see where there is a new section of conduit (indicating the repair). GPRS was called to the project after these conduits were hit to check the remaining core drilling locations prior to cutting. Upon completing the project GPRS returned to the holes where the contractor initially hit the conduits. We surveyed the area and you can see our “x” on the concrete indicating the conduit as it continues in the slab.

It is easy to see why you should consider using ground penetrating radar prior to core drilling at any location. The contractor, in this case, was told that there were no electrical conduits running in the concrete. For a small fee GPRS can ensure that you will not have any costly electrical conduit strikes. Please contact your local GPRS representative for scheduling and pricing information.

Please contact your local GPRS representative for scheduling and pricing information.

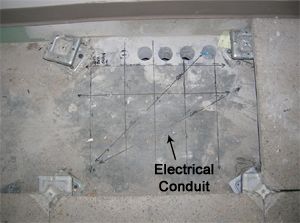

Example #2: You can see four core drilling locations in this image. The core on the right hand side of the picture is where the contractor was drilling on and elevated concrete slab and struck a conduit run in a “smurf” tube.

After striking the conduit the building demanded that the contractor “x-ray” all of the other core drilling locations. They contacted GPRS to come and use ground penetrating radar to scan 10 different core drilling locations.

The black lines represent GPRS’ layout and process to determine the presence of the electrical conduit. You can clearly see the two angled black lines indicating the location of the electrical conduit.

For a small fee GPRS can ensure that you will not have any costly electrical conduit strikes. The contractor, in this case, was told that there were no electrical conduits running in the concrete.

Please contact your local GPRS representative for scheduling and pricing information.

Why call GPRS prior to core drilling on a post tension reinforced concrete slab?

There is no doubt that whenever you, as a contractor, look to saw cut or core drill on a post tension reinforced concrete deck you should have the cables located. However, we consistently see the aftermath of people who try to cut corners and drill or cut based on construction plans or good luck. The results can be dangerous and structurally hazardous to the structure.

The picture you see below is the results of such a person core drilling prior to locating the post tension cables. The band of tendons have broken and spawled through the concrete rendering them useless and creating a repair nightmare. There is no reason, with the current technological testing methods in place, to hit rebar let alone post tension cables.

We at Ground Penetrating Radar Systems, Inc. specialize in locating all types of reinforcing steel while post tension cable is probably the most common.

The survey process is simple, fast, effective and accurate. GPRS can use ground penetrating radar to determine the location of all reinforcing steel in a 2’x2’ area in about 10 minutes. 10 minutes of our time can save you not only money but costly project down time to repair broken cables and spawled concrete.

For more information on ways you can protect your job site, personnel and investment capital please contact your local GPRS representative for a free quote or to schedule a survey.

- You can clearly see the multiple broken cables present in this band of tendons.

- You can also see the original placement of the cables and how they have moved since they were broken.